How is Matcha Made?

Do you know drinking one (1) cup of matcha is like drinking 10 cups of regular green tea in terms of its health benefits? Amazing but true!

Just remember not all matcha brands are created equal. Some are cheap while others are more expensive. The price reflects how the matcha is grown, harvested and processed. These are the key to creating the best quality matcha tea.

Order our Tea Lover’s Organic Ceremonial Matcha and discover the difference for yourself.

Here’s what you need to know. The following steps are time-tested traditions still practiced today by a rare handful of truly authentic matcha producers like My Matcha Life®.

The Six Ancient Matcha-Making Traditions

These centuries-old matcha production methods increase matcha’s beneficial nutrients and keep them intact, all the way to your frothy cup!

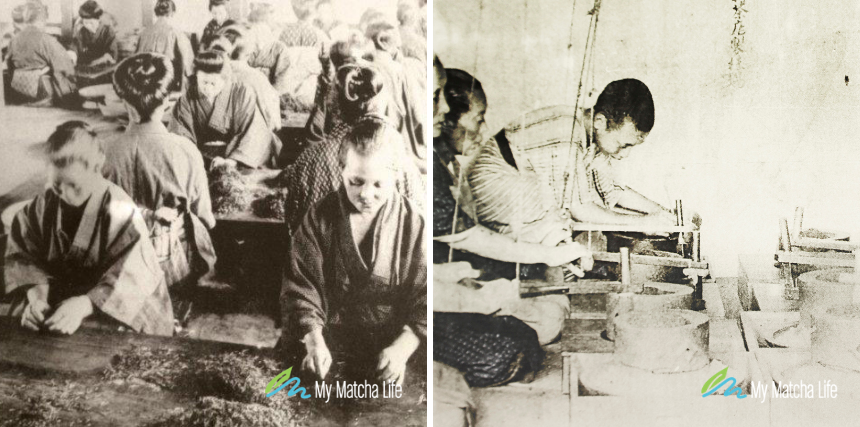

Shade Covering (Shown Above Left)

Matcha tea fields are typically covered with bamboo and rice-mat shades 2-4 weeks prior to harvest. Shading blocks the sunlight, forcing chlorophyll and l-theanine to the top outermost leaves. L-theanine makes the leaves taste smooth, and makes us feel calm, less stressed, more focused. Chlorophyll has been touted for its detoxifying abilities.

Hand Picking & Careful Selection (Above Right)

Only those outermost highly nutrient dense young tea leaves are chosen for the best quality matcha. While hand picking inevitably increases the cost of production, it guarantees that only the absolute best tea leaves are selected for processing.

Nothing beats the trained eyes and soft touch of this ancient tradition. It is, in fact, the only way to ensure the highest quality matcha tea is produced. Men and women, young and old alike, participate in the hand picking process. In some regions, students are given the first week in May off school in order to help with the spring harvest.

Light Steaming (Above Left)

Within 24 hours of being harvested, the tea leaves are lightly steamed with filtered water (removing chlorine, iron, etc.) to prevent fermentation. Steaming keeps them bright green and full of flavor and nutrients and prevents the antioxidants from being oxidized. These powerful antioxidants are why green tea’s health benefits have been so widely researched.

The steaming process is usually done at an “Aracha” processing facility near the farmers’ fields. At this point they taste a little like spinach.

Gentle Air Drying (Above Right)

The steamed tea leaves are pre-dried with air dryers, then fully dried for another 20 minutes. This continues the gentle process that ensures nutrients remain intact and are not over-processed. From here, they are bagged and placed in cold storage to preserve richness and flavor before being delivered to the “Tencha” facility for final processing.

De-Stemming & De-Veining (Above Left)

Before the Aracha tea leaves are stone ground to an ultra-fine matcha powder, they are de-veined and de-stemmed to ensure only the sweet centers of each leaf remain. These leaves are now called Tencha. A hundred years ago, this painstaking process was performed by hand. Today, producers employ air/wind chambers and agitators designed especially for tea leaves.

Stone Grinding (Above Right)

Finally, these hand-picked, shade-grown and lightly steamed, de-stemmed leaves are slowly ground between two large stones of pure granite. It takes about an hour of grinding to produce 1 ounce (30 grams) of our Tea Lover’s Organic Ceremonial Matcha.

The powder is ground to an ultra-fine 5 – 9 microns. Lesser grades have larger particles, some 15 microns or more. Overall, this labor-intensive process is the difference between high grade Japanese matcha tea and lower grades from other countries.

Heat pulverizing vs stone grinding: In the image below, you can see a heat pulverizer that produces a murky green colored powder with little nutrients, compared to the traditional granite stones that make a vibrant green powder jam-packed with nutrients.

How the Best Matcha is Made

We believe it’s important our customers know how matcha is made, especially our matcha. Being well informed simply helps us make healthier choices for both ourselves and our families.

Order your My Matcha Life® favorites today!